01 Dec2015

Here are answers to a few of the questions asked about our cold start post:

1. Are you using special kindling or fire-starter?

No, we generally use the same hemlock 1x4s that we use to crate stoves. We get the same results if we split test wood (+ 22% moisture maple) into kindling and shavings, but the 1x4s are easier and faster. The keys are surface area, and some elevation (i.e closer to the fireback is better).

2. Are you using a draft inducer?

No. The dilution tunnel has a blower (fan) and we monitor draft, flow rates, sample volume, etc.

3. Why are the Cold Start test durations so different (50 min to 70 min)?

Good question. There are a couple reasons.

First, the industry protocol doesn’t specify the size of the split pieces of cold start fuel. They leave that up to the manufacturer. Bigger pieces of cold start fuel result in a longer cold start test. All other things being equal, this is desirable if emissions are denominated by time (i.e grams/hour).

Second, the industry protocol terminates the cold start test when the cold start fuel weight reaches 10%-20% of the High Burn load (in the proposed protocol, the cold start and high burn are grafted together). So again, it is the manufacturers discretion. If emissions are denominated by time, obviously one would choose the longer duration (and the lower emissions).

Since the industry protocol suggests that results would be reported in grams/hour, these are pretty easy choices.

It is pretty clear to us that these are really two completely different tests (Cold Start and High Burn) and they need to be separated in order to produce comparable results.

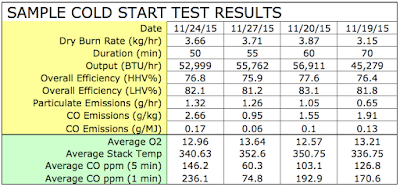

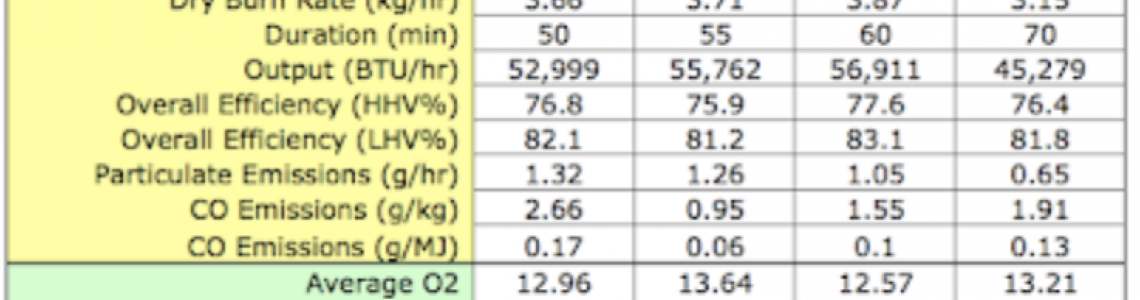

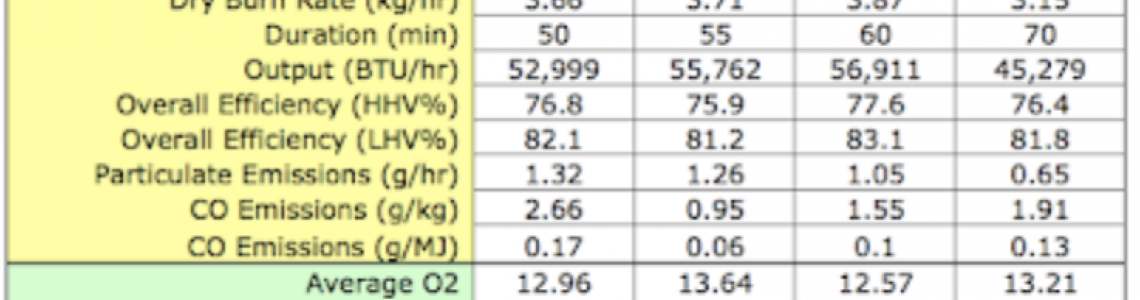

4. Can you provide average O2, Stack Temps, and CO (in ppm) for the tests?

Yes. See below. Be sure to read the notes following.

When you look at O2 and Stack Temps, you have to remember that we are starting with a completely cold stove, at ambient temps, which affects these averages.

The CO readings are very low, and we are delighted since reducing high burn emissions has been one of our main objectives over the past several years. We have focused on better high burn combustion air delivery and mixing in order to get more complete high burn combustion.

We report both 5 minute and 1 minute CO readings above. The 1 minute readings are always higher, because they capture brief spikes in CO. If readings are made at 5 or 10 minute intervals, CO spikes can be missed completely. 10 minute intervals are allowed in the proposed test protocol, which is an (easily corrected) error in my opinion. Remember, particulate sampling is continuous and cumulative.

In the 11/27/15 Cold Start Test, there was a CO spike to 1463.9 ppm for less than a minute right after loading, but the rest of the test was remarkably low. The 11/24/15 Cold Start Test had a similar beginning CO spike, but it lasted for about 3.5 minutes as opposed to less than a minute. It’s also not uncommon to get a CO rise in the middle of a test. The most interesting results are always the ones that are completely unexpected, but these are within a predictable range.