As a factory direct company, we get calls everyday with customers asking

questions about our hybrid technology. If you are curious about hybrid

technology but have not called, please read our Q&A addressing some

of the most commonly asked questions, and be sure to comment below if

you have a question that we have not addressed here.

Q .

What is the biggest difference between the new hybrid stoves and the

more traditional wood stoves made at the Woodstock Soapstone Company

(the Fireview, Keystone and Palladian)?

|

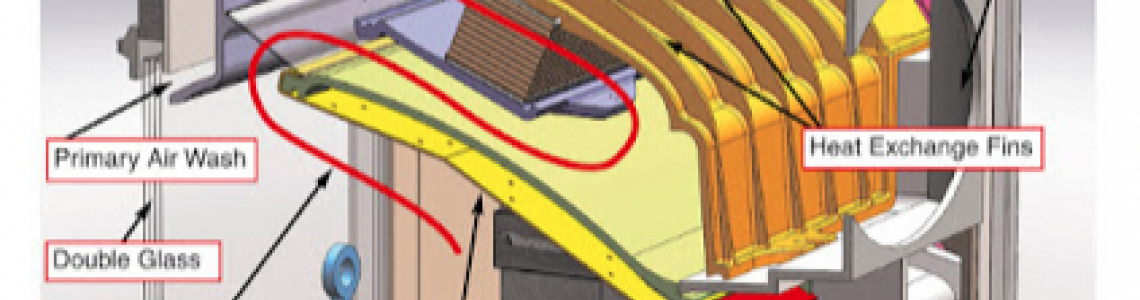

| Durafoil Steel Catalyst |

A.

The biggest difference is that hybrid technology allows us to achieve

ultra-low emissions. We developed hybrid stoves as part of a quest to

achieve lower wood stove emissions. The traditional stoves (Fireview,

Keystone and Palladian), are similar to a reliable, fuel-efficient,

family sedan (think Honda Civic). The smaller fireboxes and stainless

steel Durafoil catalysts allow our catalytic soapstone stoves to burn

cleanly and have great low emissions performance. The hybrids have bigger fireboxes and spectacular emissions performance at all outputs.

Nine years ago (in 2007) we started to research ways to make our stoves

burn cleaner. We knew that new EPA regulations were coming. Our 2007

wood stoves (Fireview, Keystone, and Palladian) already met what are now

the 2020 emissions standards, but we made them even better. We

improved the longevity and performance of the catalysts in these stoves

by making them out of Durafoil.

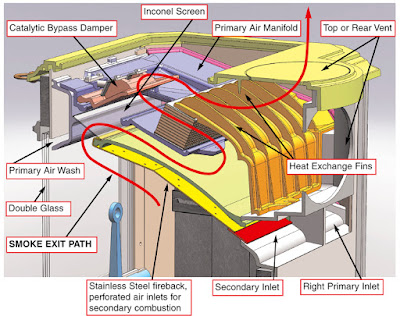

But until we introduced the Progress Hybrid Stove in 2011, all wood

stoves used either a catalytic combustor or a secondary combustion

system to meet EPA emission standards. By combining the two (catalytic

combustor and secondary system) we were able to achieve efficient,

low-emission burns throughout the entire burn range (low-medium-high)

that were dramatic, consistent and predictable.

Q . What is the difference between catalytic combustion and secondary combustion? Is one better than the other, or better together?

A.The

difference really comes down to the temperature needed for each

system (catalytic system and secondary air system) to begin to clean up

emissions. A stainless steel catalytic combustor heats up very quickly

and depending on conditions (wood, draft, operator) it can be engaged

within minutes of loading the stove, or as soon as the internal

temperature is around 400°. Catalytic stoves burn best at low to

moderate burn rates, which tends to be the most common way to operate a

wood stove for overnight and daytime burns while at work. Catalytic

only stoves test with lower emissions and greater efficiency than their

secondary air system counterparts, and do require periodic cleaning of

the catalyst to work most effectively.

The secondary air system requires higher temperatures (between

1000-1100° internally) to start burning the combustible gases in the

wood smoke. Most secondary air only stoves burn best at moderate to

moderately high burn rates, when the internal temperature is at its

peak. Due to the high temperature requirement, secondary air only stoves

have a higher tested emissions level and a lower efficiency than

catalytic style stoves.

If you combine these two separate means of lowering emissions and

increasing efficiency, you have what we would consider the “Gold

Standard”, a hybrid stove that will burn cleanly throughout all the

variations in burn rates and customer operation. Hybrid technology is

uniquely effective at high burn rates where either system may struggle

alone. The hybrid design is also very effective with large firebox

stoves, which can produce a large volume of combustible gas and

particulates.

|

| Cutaway view of the Progress Hybrid |

Q . Are there differences, other than emissions, between the hybrid woodstoves and your traditional woodstoves?

|

| One example of custom art for the Ideal Steel Hybrid |

A. Yes.

As part of the hybrid development process, we have developed ways to

make our new hybrid stoves more efficient, more affordable, and

customizable. These are all “extra” benefits from doing extended

R&D over the last nine years.

Focusing on combustion design to reduce emissions also helped us to make

our stoves more efficient. We discovered that we could make high

performance stoves that were completely affordable if they were

fabricated from steel rather than cast iron. Then we realized that we

could customize stoves made of steel, which would have been

prohibitively expensive with cast iron. Plus, making stoves out of

steel has the added benefit of being fully fabricated in our NH factory,

which ties back into greater affordability and the ability to

customize.

Q . Why are you promoting only the Hybrids during this sale?

A. Partly it’s to focus attention on the Absolute Steel Hybrid,

which we are introducing during this promotion. We’ve made a big

commitment of time, energy, and resources to cleaning up wood burning

technology, so of course we want to talk about it and of course, we want

to keep improving our combustion designs.