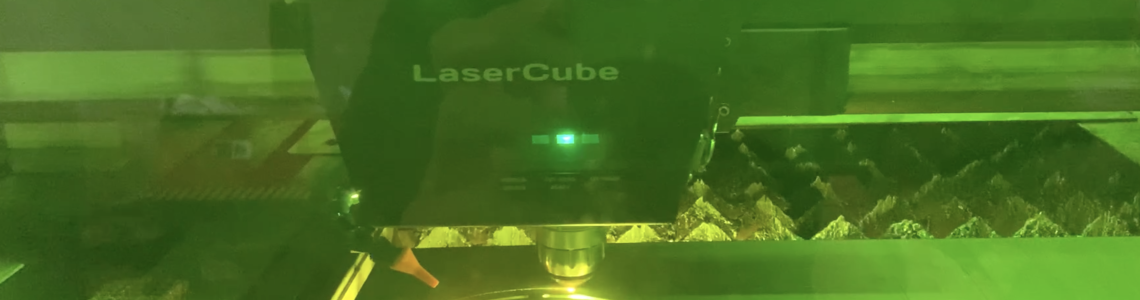

We just added to our suite of metal-cutting equipment! The IPG Laser Cube, a fiber optic laser, is the newest addition to our CNC cutting equipment; which includes a Bystronic CO2 laser and a Mitsubishi Water Jet. The IPG Laser is made in Massachusetts, about a 2 hour drive from our facility, which is pretty cool (and evidence that we can still make things in the USA! We like this company so much that we also bought a laser welder from them. The laser welder is faster, helps to reduce heat and distortion in a weld, reduces splatter, and makes it easy to weld disparate materials. More on this in a future blog post! ).

Each piece of equipment offers unique cutting capabilities. Our Bystronic CO2 Laser can cut sheets of steel up to 10 feet long, which is perfect for our steel body boxes. Our Mitsubishi Water Jet cuts without heat and will cut almost any material, including glass, wood, metal, stone, rubber, plastic, silicone, etc. The IPG Laser Cube cuts significantly faster than both the CO2 laser and water jet, including thicker 3/8" and 1/2" metal quickly and accurately, which helps to increase our efficiency and productivity.

The side burner design in the video below takes only 2 minutes to cut on the Laser Cube, the same design would take up to 10 minutes to cut on the water jet!

The design in the video and below is part of our "Ferns & Tree of Life Design" set which can be found in our Ideal Steel Geared 2U Design Book. The pictures below show the burner right off the laser cube (below left). We then countersink, sandblast, and paint for final assembly (below right)

A fully assembled Ideal Steel Hybrid cook top offers both beauty and function.